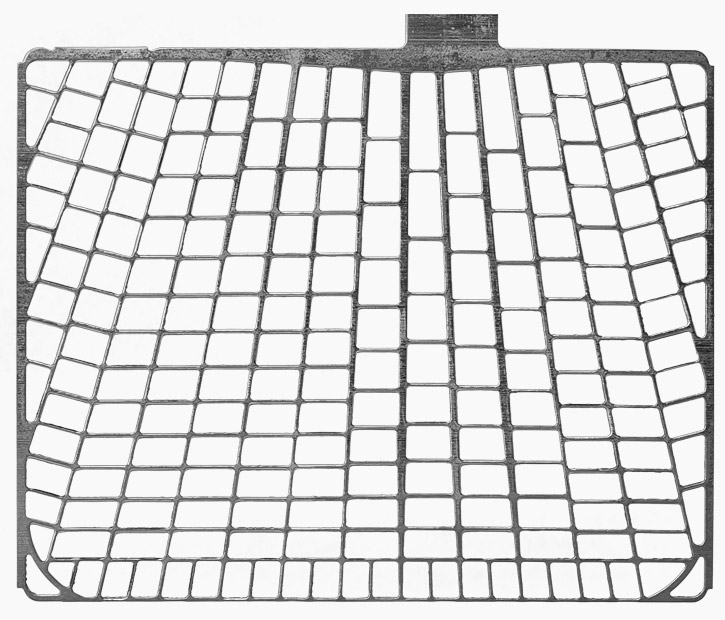

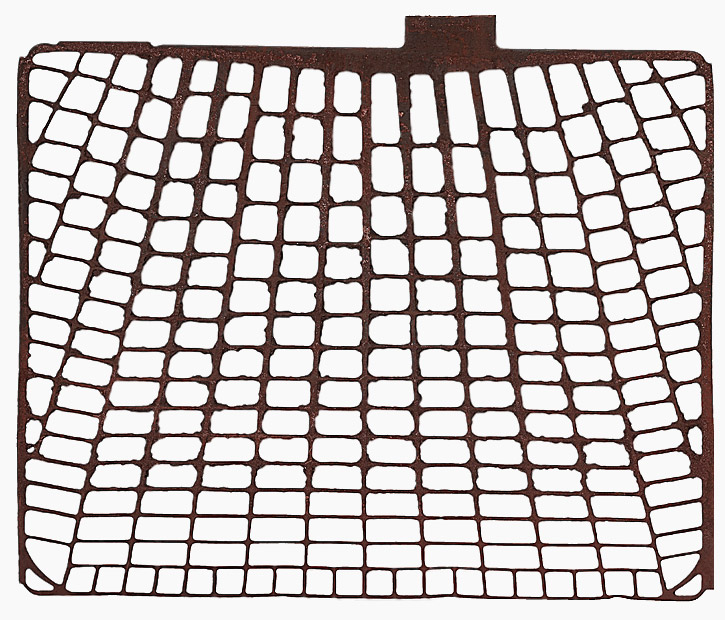

PowerFrame Grid Technology vs. Other Grids

Conventional car batteries that use bookmold or expanded metal grids are more susceptible to corrosion and expansion. Without a strong frame to preserve the strength of the grid and a grid pattern to help energy flow quickly, a battery’s grid is at risk for causing premature failure. Other production methods like these also lack the optimization and precision engineering that enable the faster recharge that PowerFrame grid technology delivers.

The grids shown in these photos were removed from batteries operating in the extreme conditions of Las Vegas taxicabs as part of a real world test conducted by a third party. Battery testing conditions were closely monitored and controlled to achieve unbiased and accurate results.

Tested in Extreme Real-World Conditions

PowerFrame grid technology has been tested in multiple cities around the world and in the most extreme, real-world conditions such as:

- Taxicabs

- Patrol Cars

- Passenger Cars

- Trucks

Extreme heat and stop-and-go driving are two of the most demanding applications a battery can face during its lifetime, which makes high heat desert taxicab fleets the ideal test environment for battery performance. Car batteries with PowerFrame grid technology routinely outlast other manufacturers’ batteries in head-to-head Las Vegas taxi-fleet studies.